|

|

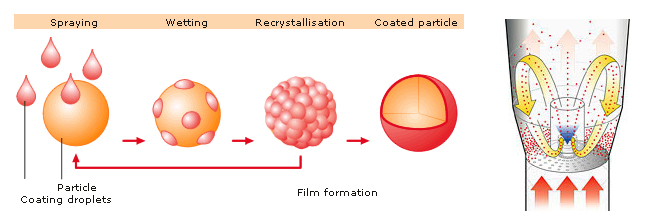

Fluid Bed Coating Spray coating can be used for all fluid bed systems, be it in batch operation or if the film is applied from a sprayed solution, suspension or hot melt. For this processing option the parameters have to be chosen to avoid agglomeration, i.e. liquid bridge between the air suspended particles. If spraying a solution or suspension the liquid only serves as a vehicle to deliver the coating material to the surface of the substrate. For hot melt coating the droplets must be small enough not to form solid bridges. The quality of the coating extensively depends on the statistical residence time of the particles in the coating zone. Bottom-spray or tangential-spray coating can be hosted by means of the relevant technical provisions. Bottom-Spray Coating:

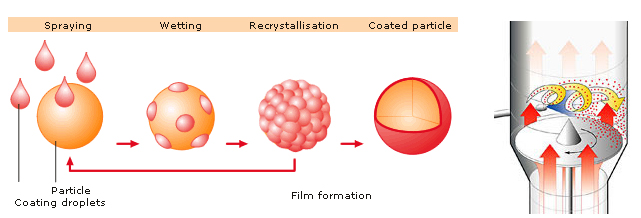

This processing option uses the energies and controls of the fluid bed to create a pneumatic mass transport inside a special insert, which consists of a perforated bottom screen with defined free areas. Most of the process air is channeled through the center via a tube, as such producing a venturi effect, which sucks the product from outside the partition past the spray nozzle. Leaving the cylindrical partition and entering the conical expansion chamber the particle velocity is dramatically reduced, excess moisture is rapidly evaporated with the dry product returning again and again through the coating zone to receive more coating material. This uniform statistical residence time of all particles in the coating zone results in a very homogenous coating. Due to the high kinetic energy provided by the pneumatic mass flow moist particles are separated, as such allowing the individual coating of even very small particles. Due to the nozzle being positioned directly inside the product and concurrently spraying a premature viscosity change of the coating droplet is avoided. All this features result in the highest possible coating quality, which is imperatively required to produce defined and reproducible drug delivery profiles. Equipment Model: LDP FLUID-BED COATER Tangential Spray Coating This processing technique is with its physical principles quite similar to bottom-spray coating,only that the production motion is provided by a motor driven rotor disc. Otherwise, the quality producing parameters are the same: 1.Uniform statistical residence time is warranted by defined rotor revolution speed

Equipment Model: LBF TURBOJET FLUID-BED GRANULATOR/COATER

Tablet coating This processing technique is with its physical principles quite similar to bottom-spray coating,only that the production motion is provided by a motor driven rotor disc. Otherwise, the quality producing parameters are the same: 1.Uniform statistical residence time is warranted by defined rotor revolution speed

High efficiency coater is mainly used for tablet,pellet,candry to carry out organic film coating,water soluble film coating,slow and control releasing coating,dropping pellet coating,sugar-coating and chocolate coating. The table is loaded in coating chamber. The coating chamber is rotated with loading tablet. The spray gun spray the coating liquid onto tablet by the transmission coating liquid of peristaltic pump.The hot air is blowed by blower.The coating liquid on tablet is dried. The moisture is evaporated by exhaust fan. It has oar inside of coating chamber so that the tablet is coated uniformly.

Equipment model: BGB HIGH-EFFICIENCY FILM COATER |