Jiangyin Snynxn Granulating Drying Equipment Co., Ltd.

Specializing in the production of pharmaceutical machinery and granulating drying equipment

WhatsApp/Wechat.: +86-13961601352

Jiangyin Snynxn Granulating Drying Equipment Co., Ltd.

Specializing in the production of pharmaceutical machinery and granulating drying equipment

WhatsApp/Wechat.: +86-13961601352

Product

category

PRODUCT CENTER

www.snynxn.com

ZLPG Spraying Dryer for Chinese Traditional Medicine Extract

Descriptions

♦ The machine adopts full close structure with primary middle and high effect air filter to fit one hundred thousand grade requirement, the tower body is provided cool air jacket to make wall temperature less than80℃,when the material stops on wall it will not to be preheated and softened, it increases the powder collection rate(95%)and will not appear mixing and sticking wall phenomenon.

♦ Basic Principle: high-speed centrifuge atomizing for the extract of traditional Chinese medicine is an application of centrifuge atomizing technique. It also uses high-speed atomizer to make liquid material into foggy droplet to contact with hot air fully to finish instant drying and get final powder product.

♦ The HESD Chinese herb extract spray dryer is specially designed to solved the problems which previous LPG spray dryer meets during drying herb extract and plant extract product as followings:

1. Raw material sticks to wall and powder collection rate is low.

2. Raw material stays on wall for a long time, resulting in coking and deterioration phenomenon.

3. It is difficult to clean and can not meet GMP requirements.

4. Low in output: r/vsd-150 type dryer can only process 50-60kg/h of raw material liquid.

♦ In view of above situation, according to properties and process requirements of traditional Chinese herb extract, our factory has researched and designed the special spray dryer for the extract liquid and got patents. It solves the historical difficult problems in drying the extract and product color after drying is good. The dried raw material does not degenerate too. It raises the economic benefit for user greatly. There are special features as below compared to ordinary LPG type spray dryer:

1. Adopt three-grade air filter, the inlet air reaches one hundred thousand grade.

2.Adopt wall cooling device, the temperature of inner wall will be less than 80℃.Even if raw material stays on inner wall surface, it will not be burnt and softened.

3.Its whole volume is 3.5 times of standard LPG high-speed spray dryer.

4.Adopt quick-open washing device, it can meet requirements for varieties production, the CIP auto cleaning device can also equip if needed.

5.Adopt wet duster and no powder dust leak out. It is in conformity with the requirements of environment protection.

6.Air sweeping device is optional.the clean effect is satisfied for some product.

7. Adopt PLC control and touch screen system to display system processing.

8. Dehumidifier and centralized collect system can be used to avoid product re-wetting and softening.

Features

1 .The tower body is equipped with cool air jacket to reduce inside tower temperature and eliminate product preheating and softening phenomenon.

2.The atomizer on top of tower is equipped with cooling device to reduce atomizer temperature, at the same time effectively eliminate material return to the top in eddy current and avoid preheat coking phenomenon.

3. Tower body and pipeline is equipped with manual quick-open cleaning hole and drain hole, CIP automatic cleaning device can also equipped if needed.

4.A automatic control constant temperature feeding tank can be equipped.

5. Manual high pressure washing tools can be offered as accessories together with spray dryer.

6. All product contact parts are made with stainless steel (or whole parts with stainless steel)

7. Product collect way adopts two grade cyclones and water film duster.

8. Air inlet temperature is automatic and continuous control which is interlocked with feeding.

9. An air sweeping device can be optional for some product.

10. It can equip primary, middle and high efficient air filter to get one hundred thousand grade clean air.

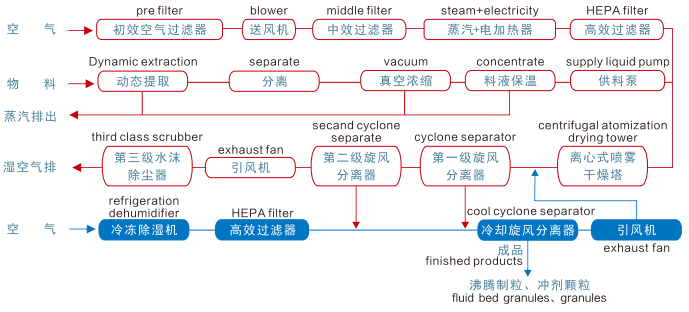

Flow chart

Technical Parameter

| 型号 spec |

ZLPG-5 | ZLPG-10 | ZLPG-25 | ZLPG-50 | ZLPG-80 | ZLPG-100 | ZLPG-150 | ZLPG-200 | ZLPG-300 | |

| 水份蒸发量 evaporation capacity(kg/h) |

5 | 10 | 25 | 50 | 80 | 100 | 150 | 200 | 300 | |

| 料液处理量 process amount of material |

6-7 | 12-14 | 25-34 | 50-68 | 80-108 | 100-135 | 150-203 | 200-270 | 300-406 | |

| 成品产量 output of finished product(kg/h) |

1-2 | 2-4 | 4.8-7.2 | 9.2-14 | 14.8-22.4 | 18.4-28 | 24-42 | 36.8-56.4 | 55-85 | |

| 湿物料含固量 solid content of material liquid{) |

18-25 | |||||||||

| 成品含水率 moisture content of finished |

3-5 | |||||||||

| 电功率 electric power(kw) |

36 | 45 | 63 | 99 | 132 | 153 | 204 | 246 | 330 | |

| 加热源 heat source |

蒸汽加电 Steam pius electricity |

|||||||||

| 产品捕集方式及效率 collecting method of product and its efficiency |

两级旋风除尘器或一级旋风除尘器及一级湿式除尘器≥98% Two-grade cyclone or one-grade cyclone and one-grade web-method dedusted of 98% |

|||||||||

| 自控仪表 automatic control meters and |

热风温度及排风温度指标,自动调节温控仪 indicator of not air and exhaust air temperature |

|||||||||

| 进风温度 temperature of air inlet(*C) |

150-200 | |||||||||

| 出风温度 temperature of air outlet(°C) |

80-100 | |||||||||

| 外形尺寸 overal diimensions(mm) |

长L | 5000 | 5500 | 7000 | 8000 | 9800 | 11000 | 12200 | 14100 | 15000 |

| 宽W | 3000 | 3500 | 4000 | 5000 | 5700 | 6200 | 7000 | 7800 | 9000 | |

| 高H | 4500 | 4600 | 5200 | 6500 | 7600 | 8100 | 9000 | 9850 | 11100 | |

HOME | ABOUT US | TECHNICS PROCESS | PRODUCT CENTER | ENGINEERING PROJECT | NEWS CENTER | E-CATALOGUE | CONTACT US | 中文版

Copyright(C)2021, Jiangyin Snynxn Granulating Drying Equipment Co., Ltd. All Rights Reserved. Supported by ChinaChemNet ChemNet Toocle Copyright Notice 备案序号:苏ICP备18029340号