Jiangyin Snynxn Granulating Drying Equipment Co., Ltd.

Specializing in the production of pharmaceutical machinery and granulating drying equipment

WhatsApp/Wechat.: +86-13961601352

Jiangyin Snynxn Granulating Drying Equipment Co., Ltd.

Specializing in the production of pharmaceutical machinery and granulating drying equipment

WhatsApp/Wechat.: +86-13961601352

Product

category

PRODUCT CENTER

www.snynxn.com

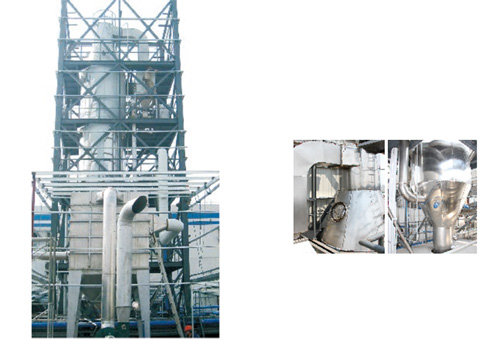

YPG Pressure Spraying Granulating Dryer

Operation method

♦ This set is an apparatus that can finish drying and granulating at the same time. The needed ball granule with certain size and ratio can be got in accordance with requirements of process to adjust pressure, flow, and size of atomizing hole.

♦ The working process of this set is as follows:the liquid of raw material is pumped in through diaphram pump. The liquid of raw material is atomized into tiny droplets. Then it falls down with hot air in co-current form. Most parts of powder material is collected through the discharge port at the bottom. The exhaust and fine powde「are separated by goingthrough the cyclone, and the exhaust is discharged by draft fan. The outlet of fan can also be equipped with two grades of duster. And its recovery ratio will be 96-98%.

♦ The tower body, pipes and separator of this set contacting with raw material are made of SUS304. There is enough layer of heat preservation between inner and outer case of tower body. The filled material is fine glass cotton. The tower body is also equipped with observation door, sight glass, lamp-house and control meters and instruments that are controlled and displayed through electric control panel.

♦ The heat source of this set may be steam or electric heater, with the features of convenient operation.quick start, compact structure clean hot air etc. Moreover, installed control and regulation device of the electric heater inside eletctric control cabinet, the inlet temperature can be controlled through stepless regulation. The steam, coal fuel or oil fuel can be applied to the place where has not electricity. It can replace electric heating partially or fully. The factory can provide different heating ways in accordance with the practical conditions of customer.

Features

♦ The drying speed is fast. The surface area of liquid raw material after being atomized will be increased greatly.95-98% of moisture can be vaporated at the moment. The time of drying needs about ten seconds to several tens of seconds. It is suitable for drying heat sensitive material particularly.

♦ The finished product is ball granule with uniform size. Its fluidity and solubility are good. The purity of product is high and its quality is good.

♦ Its scope of application is wide. According to the characteristics of raw material, it can use hot air to dry and can also use cool air to granulate. It has strong adaptability to raw materials.

♦ Its operation is simple and stable and its control is simple and convenient and is easy to realize automatic operation.

Scope of Application

Granulating through atomizing dry:

Chemical industry: organic catalyst, resin, synthetic washing powder, oils, thiamin, dyestuff, intermediate of dyestuff,white carbon black, graphite, ammonium phosphate and so on.

Foodstuff: amino acids and similar substances, flavoring, protein, starch, dairy products,extractive substance from coffee, fish powder, extractive substance from meat and so on.

Pharmaceutical: Chinese patent medicines, agrochemicals,antibiotics, medical drinking agent and so on.

Ceramics: magnesium oxide, kaoline, all kind of metallic oxide, dolomite and so on.

Granulating through atomizing: all kinds of fertilizer,aluminum oxide, ceramics powder,pharmaceutical, heavy metallic super hardness steel, chemical fertilizer, washing powder,Chinese patent medicines and so on.

Process flow chart

1. Air filter

2. Air filter

3. Steam heater

4. Electract heater

5. Hot air rectifier board

6. Pressured atomizer

7. Rain drying tower

8. Buffer tank

9. Liquid tank

10. High-pressure pump

11. Refrigeration dehumidifier

12. Power return blower

13. Cyclone separator

14. Cloth bag deduster

15. Induced fan

16. Water film duster

17. Power return pipe

18. PLC control cabinet

_副本(1).png)

Technical parameters

| 型号spec 项目item |

YPG-25 | YPG-50 | YPG-100 | YPG-150 | YPG-200 | YPG-300 | YPG-500 | YPG-1000-2000 | |

| 水份蒸发量 water evaporation capacity |

25 | 50 | 100 | 150 | 200 | 300 | 500 | ||

| 隔膜泵 diaphragm pump |

功率power (kw) | 0.35 | 4 | 7.5 | 11 | 15 | 22 | 30 | 该指标按实际情况确定 The index can be affirmed in accordance with practical conditions. |

| 压力pressure(Mpa) | 根据物料实验效果在0.6-5之间调节,一般操作在1-3之间。 It can be regulated from 0.6 to 5, in general, it will be from 1 to 3. |

||||||||

| 加热方式 heating way |

电 electricity |

电+蒸汽 electricity+steam |

电+燃煤(油)热风炉 electricity+coal fuel oilhot air furnace |

||||||

| 塔身直径 diameter of tower body (mm) |

1300 | 1800 | 2400 | 2600 | 2800 | 3200 | 3800 | ||

| 设备总高total height (mm) | 7800 | 9200 | 11600 | 14000 | 15300 | 17100 | 19000 | ||

1. The evaporated amount is related to characteristics of raw material. The evaporated amount listed in the table is related to temperature. The data can be used for reference only.

2. The atomizing pressure and Model of pump will be equipped in accordance with the amount of raw material to be treated and the size require of product.

3. The power of fan should be increased suitably after equipped with cloth bag duster.

.gif)

HOME | ABOUT US | TECHNICS PROCESS | PRODUCT CENTER | ENGINEERING PROJECT | NEWS CENTER | E-CATALOGUE | CONTACT US | 中文版

Copyright(C)2021, Jiangyin Snynxn Granulating Drying Equipment Co., Ltd. All Rights Reserved. Supported by ChinaChemNet ChemNet Toocle Copyright Notice 备案序号:苏ICP备18029340号