Jiangyin Snynxn Granulating Drying Equipment Co., Ltd.

Specializing in the production of pharmaceutical machinery and granulating drying equipment

WhatsApp/Wechat.: +86-13961601352

Jiangyin Snynxn Granulating Drying Equipment Co., Ltd.

Specializing in the production of pharmaceutical machinery and granulating drying equipment

WhatsApp/Wechat.: +86-13961601352

Product

category

PRODUCT CENTER

www.snynxn.com

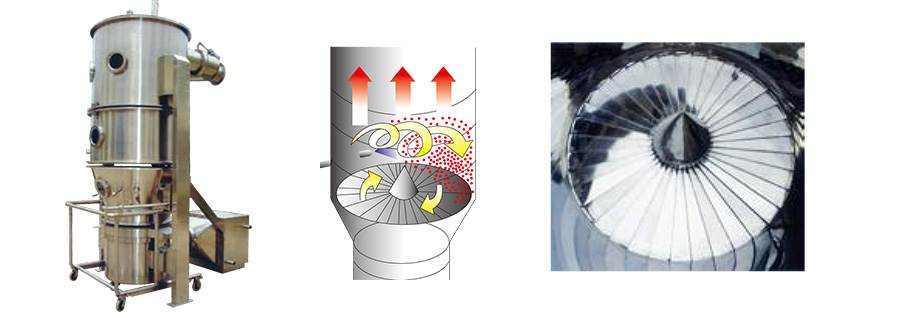

LBF Turbojet Fluid-bed Granulator Coater

Descriptions

LBF Turbojet fluid-bed granulator coater has vane-shape bottom of hopper which has a certain lean, let the air flow pass through the rift then form circle-shape strong air flow, it makes material rotate as regular turbojet movement. Meanwhile the pneumatic nozzle installed under left wall spray binder or coating liquid into turbojet material, in this way granule or successive even film can be obtained.

It is widely used in coating of powder, granule, pellet, enteric-releasing, slow and control releasing, and coating of smell covering, dam proof, antioxidation, water proof, heat isolation dyeing and separation etc.

Features

◎Rotational flow drives air distributor in order to guarantee that material can move in order.

◎Because of fluidization of rotational flow, it overcomes channel flow and died comer.

◎The prepared granule is porous and can solve quickly and also has certain strength and is not easy to break.

◎For materials such as Chinese traditional medicine and moisture-adsorbed materiality are easy to operate.

.jpg)

|

规格 Specification |

3 | 5 | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 200 | 300 | 500 | 800-100 | ||

|

投料量Capacity |

Kg/批 kg/batch | 3 | 5 | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 200 | 300 | 500 | 按用户要求设计 By client |

|

|

原料容器容量 |

L | 12 | 22 | 45 | 100 | 155 | 220 | 300 | 420 | 550 | 670 | 1000 | 1500 | ||

|

风机功率Power of fan |

Kw | 4 | 4 | 5.5 | 7.5 | 11 | 15 | 18. 5 | 18.5 | 22 | 22 | 30 | 45 | ||

|

噪音Noise |

db | 风机隔离处理噪音小于75分贝 No more than 75db Separated of fan |

|||||||||||||

|

压缩空气 Compressed air |

压强 Pressure | Mpa | 0.6 | ||||||||||||

| 耗量 Consumption |

M3/min |

0. 4 | 0. 4 | 0.6 | 0.9 | 0.9 | 0. 9 | 1. 1 | 1. 3 | 1.6 | 1.8 | 2.4 | 3 | ||

|

蒸汽 |

压强 Pressure | Mpa | 0.4- 0.6 | ||||||||||||

| 耗量 Consumption | Kg/h | 71 | 60 | 99 | 120 | 130 | 140 | 161 | 180 | 310 | 450 | ||||

|

电加热功率 |

Kw | 6kw | 9kw | ||||||||||||

|

主机尺寸 |

H1(mm) | 2870 | 2960 | 3140 | 3290 | 3400 | 3630 | 3720 | 3890 | 3970 | 4440 | ||||

| H2(mm) | 2600 | 2600 | 3230 | 3520 | 3630 | 3880 | 3890 | 4120 | 4210 | 4360 | 4440 | 4960 | |||

| H3(mm) | 2410 | 2410 | 3630 | 2720 | 2900 | 3050 | 3160 | 3390 | 3480 | 3650 | 3710 | 4160 | |||

| B1(mm) | 760 | 860 | 1110 | 1160 | 1360 | 1460 | 1560 | 1660 | 1760 | 1860 | 2060 | 2260 | |||

| B2(mm) | 1060 | 1660 | 1760 | 1860 | 2260 | 2460 | 2660 | 2860 | 3060 | 3260 | 3660 | 4060 | |||

| L(mm) | 850 | 1000 | 1100 | 1250 | 1570 | 1530 | 1530 | 1650 | 1650 | 1650 | 1750 | 1850 | |||

All datas are for reference only. According to the condition of material, our factory has the right change but not notice, pardon

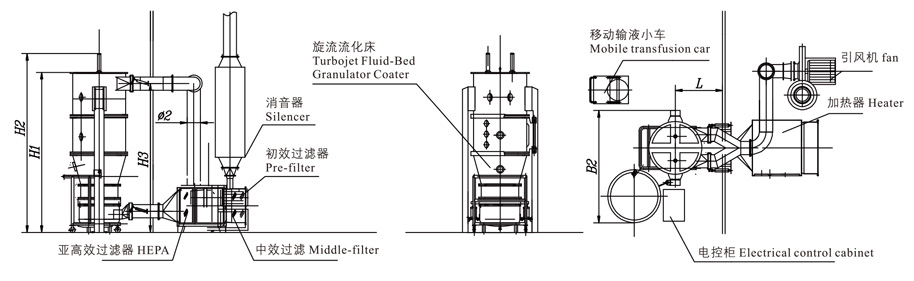

Process flow chart

HOME | ABOUT US | TECHNICS PROCESS | PRODUCT CENTER | ENGINEERING PROJECT | NEWS CENTER | E-CATALOGUE | CONTACT US | 中文版

Copyright(C)2021, Jiangyin Snynxn Granulating Drying Equipment Co., Ltd. All Rights Reserved. Supported by ChinaChemNet ChemNet Toocle Copyright Notice 备案序号:苏ICP备18029340号